Client: ProsysDev

Value: £67k

We were asked to look at this project via an enquiry from our website, the customer had looked around and felt we could help. When he contacted us, our first reaction was that it was around the M25, and miles away, surely someone closer could build a partition. The problem was that the customer wanted a bit more than a partition as the new room had to sit on the edge of a mezzanine floor and he was unsure about Building Regulations. The people he had contacted just wanted to give him a price for glass walls, without listening to what else he needed and gave no reassurance that it would actually comply with regulations.

For us, it was unusual to find a client that understood that there were Building Regulation issues to be addressed. The customer wanted a piece of paper at the end of the work to say that it complies and everything is fine as that was the right thing to do. When they took on the unit we think it helped that part of the specifications was a mezzanine floor that had been fire rated and was suitable for offices above, and that must have triggered a question.

All the other suppliers of partitioning just wanted to build a wall and that was it. Didn’t even want to visit.

The Next Step

After speaking with the client, we decided to just have a quick look for him if he could send over some details and see what we thought and give some budget costs. We just wanted to see how we could help, so let us have a quick look.

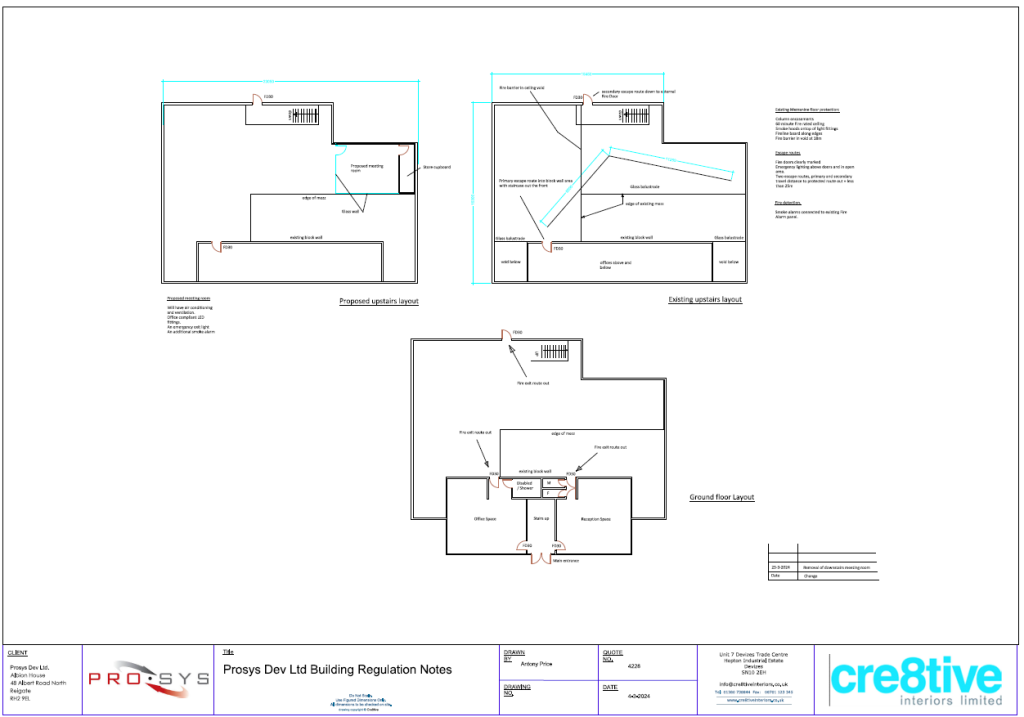

These are the details that were sent to us, pretty good actually.

Building Regulations

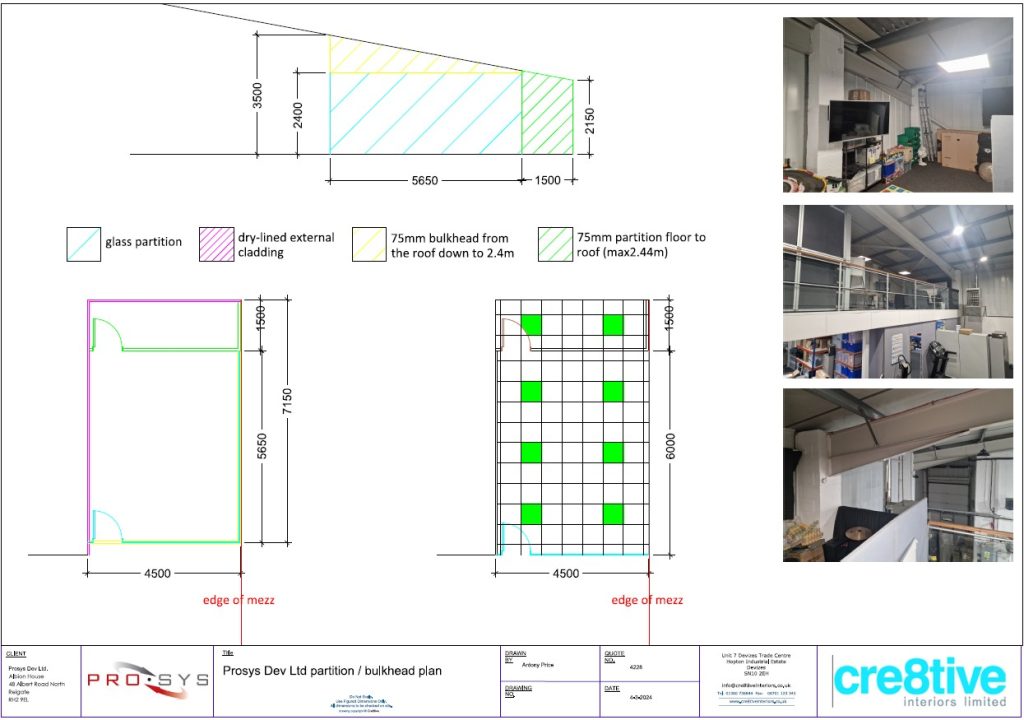

Looking at it initially, slightly tricky. The handrail would be in the way and we would have to remove it, and build the wall to the edge. The other bit that was quite hard was the sloping roof, we could have to build up to it and deal with the beams and make it look right. The customer was quite right, and we had to check with Building Regulations which is what we did, free of charge. The key things were that there were two means of escape with the 45 linear meters, so that was fine. The room needed fresh air ventilation, via a VAM unit, any glass to be fitted, which was our preferred options needed to be a special thickness as it is right on the edge at height. Again not a problem. We would also quickly need to check the mezzanine floor itself, to make sure it had the right fire protection. As it happened there was no cavity barrier inside the suspended ceiling underneath as the floor was long than 18 linear meters, and it needed one, so we put one in.

There are other things we did, but in essence, none of this was an issue.

We gave a budget cost, subject to a visit and that was ok, we visited and they also wanted their toilets refurbished. So we refurbished their toilets as well.

Design work, specifications

We always produce a drawing, initially we do this anyway so we can cost the project properly and not just guess everything which we know many people do.

The drawing needed to be tided a bit, although not to architectural standards, it is good enough to explain what needs to be done.

Construction, work in progress.

We liked the design of this project, the idea was to build a bulkhead suspended down from the roof which would form a rectangular opening to accommodate smart modern looking glass walls. Another tricky bit, as well as having to remove the handrail was to follow the shape of the roof and box the beams to make it look right. There were a couple of beams at different angles but we made it look right.

To build the walls around the meeting room out of tradition demountable partition systems, with plasterboard and double glazed windows would have actually been more expensive with what we were proposing, and certainly it would not look as good.

There was a small bit of detail in the construction that we quite liked. When we fitted the fresh air unit, the VAM unit, we prepared all of the ductwork which gets hidden by the suspended ceiling above, but also included extra ductwork to feed the potential downstairs office below the mezzanine.

The interior wall for the meeting room we built flush over the steel work, that give us a cavity where we could run the 200mm diameter ductwork down the walls, through the mezzanine floor and capped off ready for the room below. The ductwork needed fire dampers in them for fire protection purposes; preventing potential fire travelling from the upstairs to the downstairs through the pipework in the unlikely event of a fire. The dampers are also required to meet Building Regulations.

Toilet refurbishment

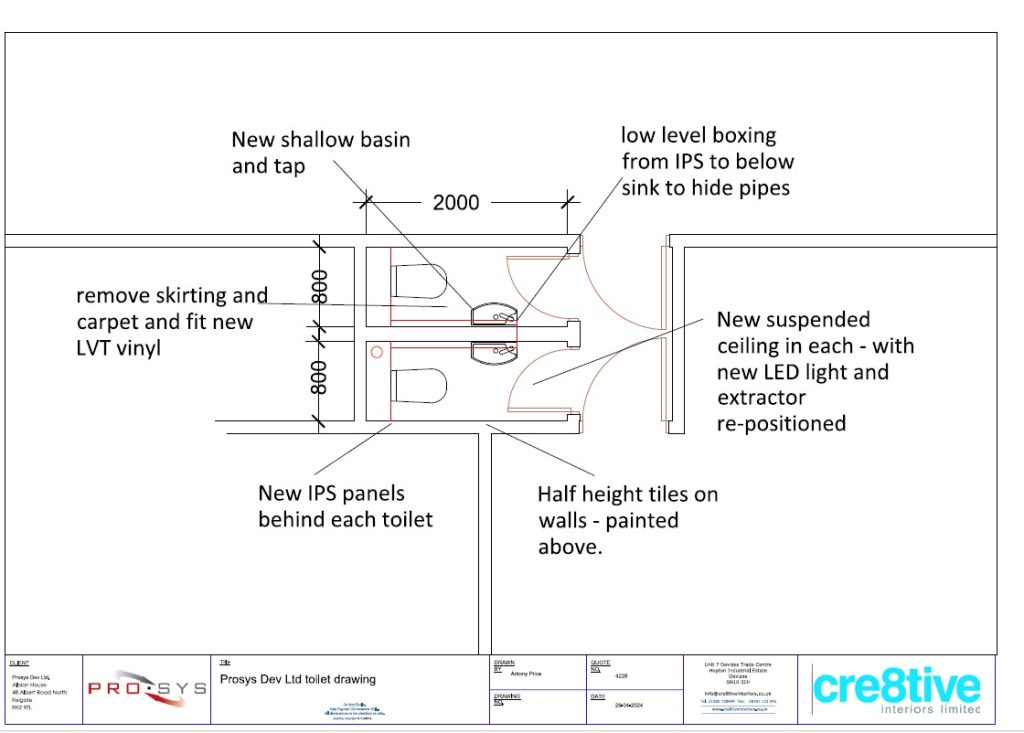

As mentioned previously in this post, the initial enquiry was not to refurbish the toilets but when we visited, we said what else we could do and they needed something doing to them.

Although small, we could hide the plumbing by using IPS systems, which is a system of enclosing pipework and cisterns behind a closed panel. Often seen in commercial centers, like shopping centers, motorway service centers.

We could also box the pipework, tile the walls, paint it, change the flooring, fit a new suspended ceiling and lights. Quite a bit really for such small spaces.

It is not possible to get lots of trades to do this type of work.

Toilet refurbishment progress photos

Some work in progress and completed photos

One of the problems in refurbishing small toilets is that they need lots of different trades, and there is not enough room in them to have lots of people doing different things.

For example, in these toilets we needed:

- a plumber to disconnect / reconnect the existing and new.

- Someone to build and fit the IPS panels, (needs a carpenter to cut the panels to size, sit them squarely)

- a plumber to fit the sanitary wear to the IPS panel as it is being fitted.

- A tiler to fit new wall tiles straight and flat.

- A decorator to prepare the walls and paint them.

- A suspended ceiling fitted to fit a new suspended ceiling

- An electrician to disconnect the existing light and fit a new one, someone to fit a new toilet extraction system.

- A flooring contractor to uplift the existing and supply and fit a new wood effect vinyl floor planks.

- Someone to fit the new towel rail, toilet role dispenser, mirror, door signs.

Larger toilets are much easier as all of the activities can be scheduled and planned in as the elements usually take longer than a day. In this case there is not enough work to allow to bring in separate trades to do individual elements, planning and timing of those events would mean that doing the toilets would take months and cost a fortune. Luckily we have a fitter that can do all of the tasks, including the plumbing works. We were onsite anyway doing the electrics for the new offices, so it was easy for them to drop over onto the toilets to sort out the light fittings and extraction. Not so easy for anyone to do this type of work. Most plumbers would not know how to deal with the IPS system as there are commercial systems.

Some completed photos

The following photos were supplied by the client after we had left site. They show the boardroom table and chairs, and the comments from the customer is that they are very pleased with the final result and use the ideas wall along the long wall to good effect.

If you have any partitioning requirements that are perhaps a bit complicated and you are not sure on how things can be done, then we are sure we can help.

Please call 01380 73 8844 or email us via the contact form on this website, or at [email protected]