Client: RTS

Value: £33k

Although the main title to this project post relates to the Vaulted roof design of the space, half the value of the project was for office furniture. A mixture of desks, soft seating, chairs and stools all designed with a selection of vibrant colours. The desks had dark charcoal worktops and white desks frames which looked pretty cool.

The customer was already in one building and wanted to expand into this one. They wanted a meeting room at one end by the main entrance like their existing space, that was built using an engineered timber system which would have cost an absolute fortune to build. We chose a different method, much more modern as well.

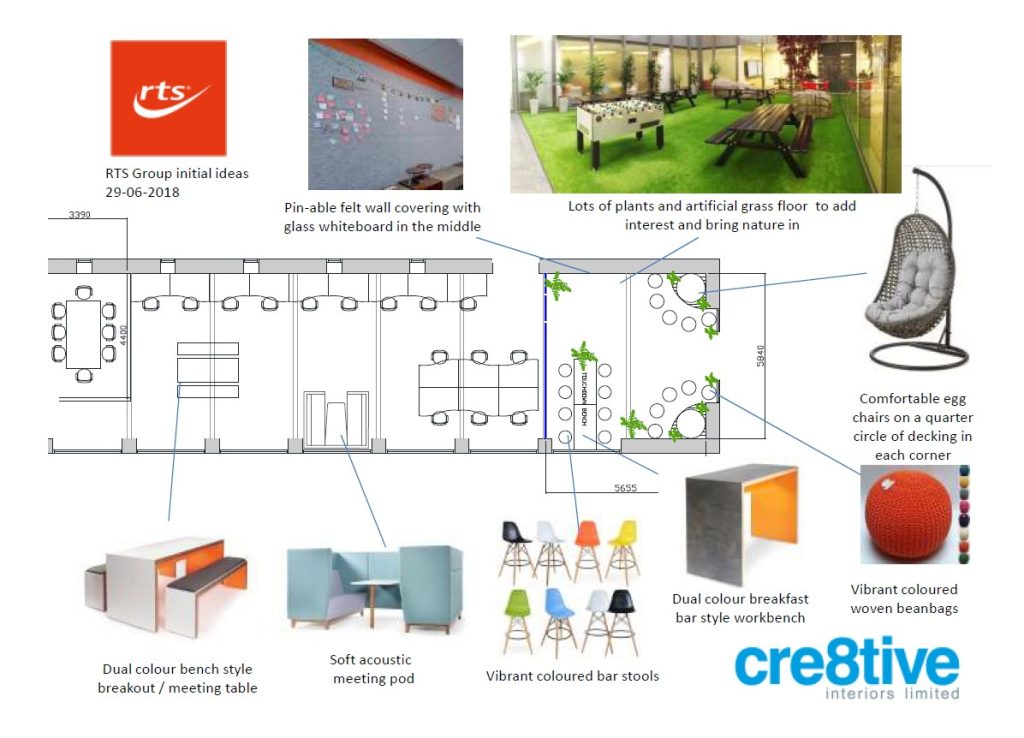

They also needed a breakout space away from the desks, where they could also brainstorm and do some problem solving away from the formality of meeting rooms. The space at the end of the building seemed ideal, so we allocated that space for that function.

The Vaulted Roof

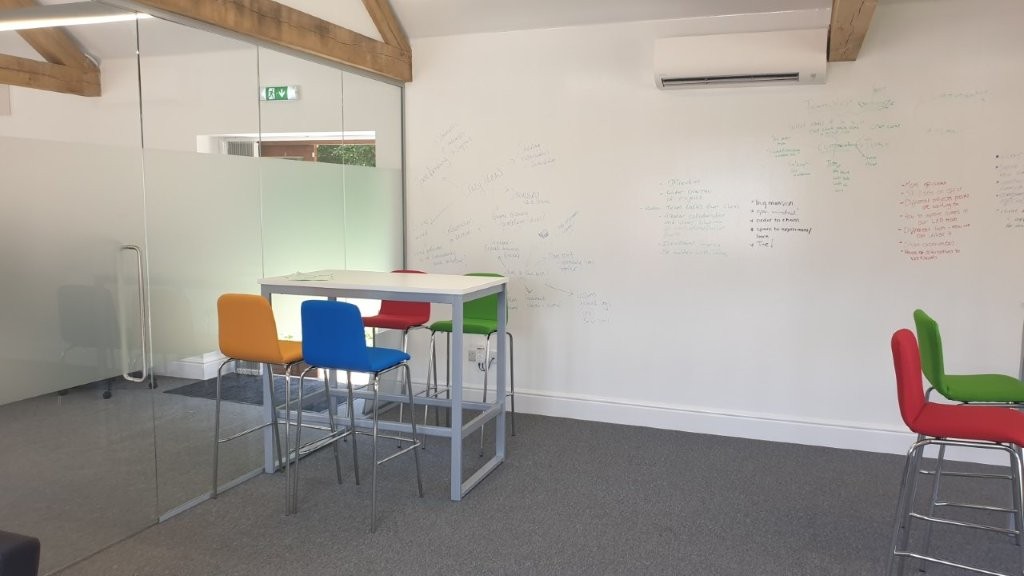

The actual office space looks lovely, nice open roof space with oak beams. The building as well is in an amazing environment, very rural, lots of nice space, plenty of parking. However, as is common with many spaces built by builders, it is not very practical. Looks nice, but for an office space, not great. All of the wall surfaces are hard plastered walls and painted, and the high roof offers little in acoustic performance, the saving grace was at least they had a carpet.

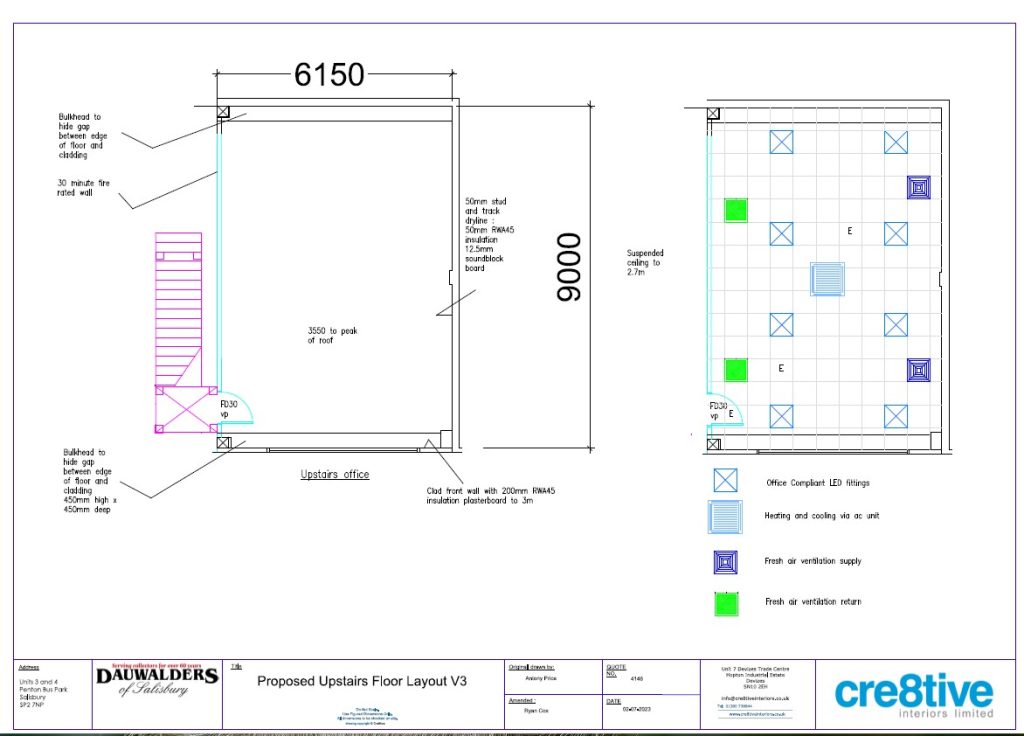

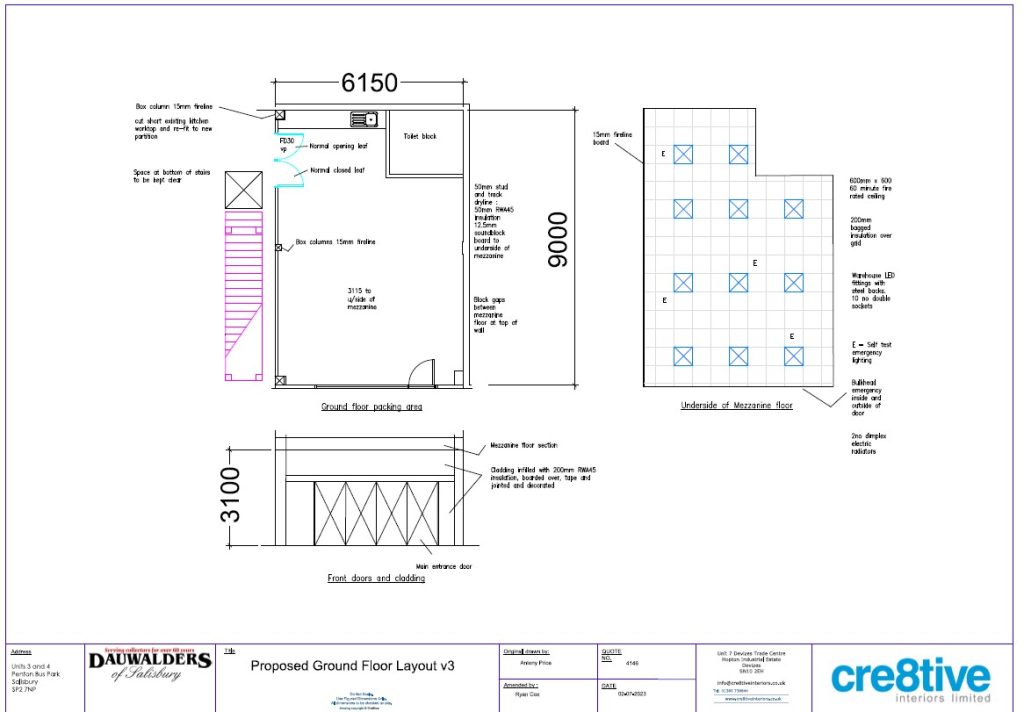

Separating off the space into rooms therefore presents a bit of a problem. They liked the idea of glass walls, so we could build up to the roof beams, and then above the gaps would need to be filled in to prevent noise going through the trusses.

The meeting room needed at the front would need the trusses blocked in, and a new timber beam run along the side with the wall above filled in, with glass underneath in an ‘L’ shape. Along with an entrance door into the main office space.

The ideas room at the end would be more straightforward, build the glass up to the truss, and then infill all of the gaps above.

Initial Plans and Ideas

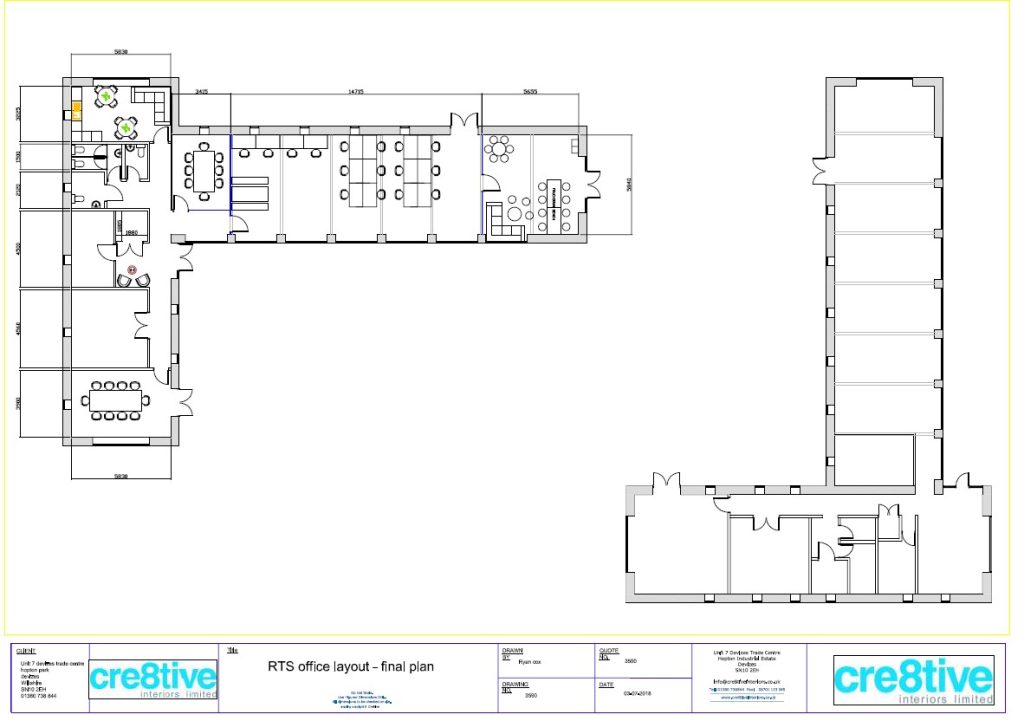

As always, we draw everything anyway. The main reason is so we can cost things accurately, and we do not always need to give the drawings to the client, but in this case, they paid us separately for the drawing and design work which was nice, and a bit unexpected but they were happy to do this. We also said that should they go ahead with the proposals, we would credit back the cost of the drawing work against the work which is what we did.

Infilling the Trusses and Glass Walls

In two of the overhead trusses, we had to allow to infil these with plasterboard and steel which was always going to be a time consuming job. Each section of the truss is different, it would have been very difficult and expensive to get these infilled with glass and then there is the sound performance issue with glass. Each of the sections we added insulation into the gaps.

Remaining Construction Photos

Below shows the remaining construction photos, some show the assembly of the desks using a ‘beam’ system, with shared leg frames. The main advantage in using a beam system is that the support leg frames are shared amongst adjoining desks, hence reduce the costs. Shared leg frames gives more leg room under the desks. The central spine of the desk cluster also has a cable management tray which keeps all of the power and data off the floor. The cabling can then be run from the edge of the walls, rather than worry about floor boxes near where people sit. Floor boxes would need cables running up from the floor boxes to the desks. Much neater to have cable management in the desks themsleves.

Also shown is the write on ideas wall, the glass writing board, the meeting tables, boardroom table and the other furniture in the rooms.

Space Planning and Design Work

If you are unsure of what can be done with a space, we really like to do the space planning and design work, working with what space you have. Making the most of the features that are in the building and maximising the light using glass walls, introducing vibrant colours and having an area to stimulate ideas were all aspects of this project that were enjoyable to do. If you have a project similar, and have any questions we would love to be involved in your project. The first visit is always free and the advice is free as well. If you are not sure what is involved you are not sure on how things can be done, then we are sure we can help.

Please call 01380 73 8844 or email us via the contact form on this website, or at [email protected]